AI Warehouse Robot

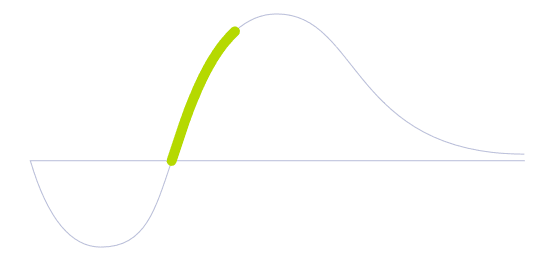

Technology Life Cycle

Marked by a rapid increase in technology adoption and market expansion. Innovations are refined, production costs decrease, and the technology gains widespread acceptance and use.

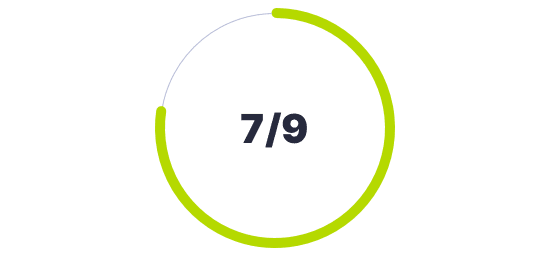

Technology Readiness Level (TRL)

Prototype is fully demonstrated in operational environment.

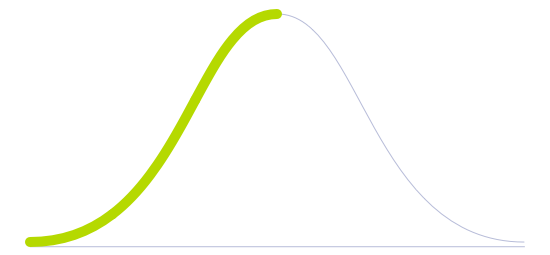

Technology Diffusion

Adopts technologies once they are proven by Early Adopters. They prefer technologies that are well established and reliable.

One of the biggest challenges for the retail and shipping industries is to sort, pick, pack, and ship items purchased by customers, delivering their purchases in the shortest amount of time possible. For that to happen, physical robots embedded with artificial intelligence are beginning to be implemented in warehouses worldwide. Most of them are assisted by a human, who oversees, provides direction, monitors, and sometimes directly operates the machine (either physically or remotely).

While coexisting with robots, this new alternative to manual labor jobs is not supposed to take the place of human labor. Although it is a potentially viable possibility for entrepreneurs that can't afford many employees, it also aims to increase the scale of production. The long-term goal for these machines is to learn from human inputs and carry out their designated tasks autonomously, driving down labor costs while decreasing delivery times. However, these robots have limited interactive capabilities between their software and humans. As such, there are still many soft skills that need to be practiced and developed for personalized communication to become a featured benefit.

Future Perspectives

As robots become more intelligent and reliable, the human labor force employed at supply chain centers could decrease drastically, making facilities nearly human-free. For that to occur, not only would robots have to mimic human activity, but entire working systems would have to be developed to allow machines to work by themselves. Nowadays, since much of the supply chain in warehouses depends on technology handled by humans - such as ticketing and tagging, this process must undergo in-depth digitalization and dematerialization before the retail and logistics industries go fully autonomous.

Image generated by Envisioning using Midjourney