Biomimicry

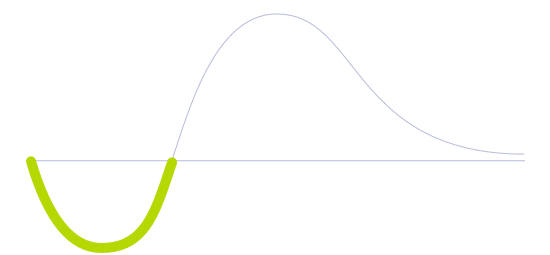

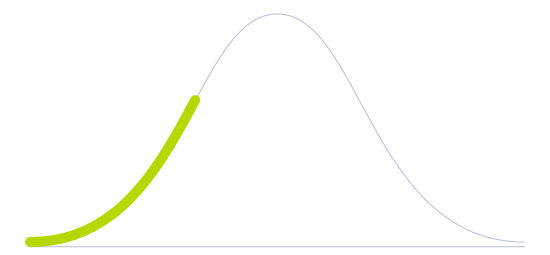

Technology Life Cycle

Initial phase where new technologies are conceptualized and developed. During this stage, technical viability is explored and initial prototypes may be created.

Technology Readiness Level (TRL)

Validation is conducted in relevant environments, where simulations are carried out as close to realistic circumstances.

Technology Diffusion

Embrace new technologies soon after Innovators. They often have significant influence within their social circles and help validate the practicality of innovations.

Also known as biomimetics, biomimicry tackles various manufacturing challenges, from enhancing sustainability to optimising product design by harnessing the ancient wisdom of nature to solve complex problems. This approach offers solutions to issues like resource scarcity, energy efficiency, and waste reduction by emulating nature's ingenious designs. For instance, in product development, mimicking the structure of spider silk can lead to lighter yet more robust materials, ideal for aircraft components or safety gear.

Biomimicry involves studying biological systems and processes. Engineers and scientists delve into nature's designs, such as the lotus leaf's self-cleaning ability or the human circulatory system's efficiency, and then apply these principles to manufacturing. By mimicking these natural mechanisms, manufacturers can create more sustainable and efficient products and processes.

This set of solutions paves the way for innovative, eco-friendly materials and processes, reducing the industry's environmental footprint. Moreover, it fosters a more circular economy by emulating how nature efficiently recycles and reuses resources. As we grapple with the climate emergency and resource depletion, biomimicry emerges as a game-changer in the pursuit of sustainable, forward-thinking manufacturing.

Image generated by Envisioning using Midjourney