4D Printing

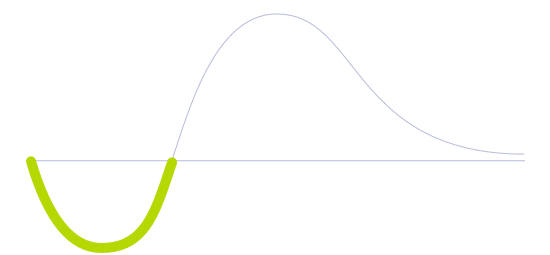

Technology Life Cycle

Initial phase where new technologies are conceptualized and developed. During this stage, technical viability is explored and initial prototypes may be created.

Technology Readiness Level (TRL)

Validation is conducted in relevant environments, where simulations are carried out as close to realistic circumstances.

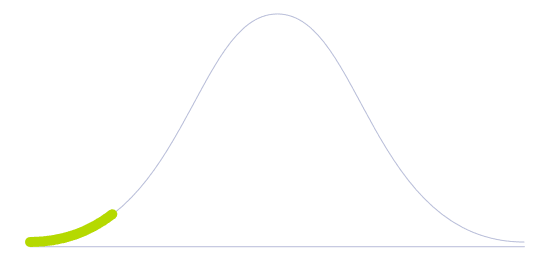

Technology Diffusion

First to adopt new technologies. They are willing to take risks and are crucial to the initial testing and development of new applications.

4D Printing is a fabrication process that, with the help of a 3D printer, constructs objects from materials such as auxetics, shape-memory polymers, and hydrogels that fall in the category of metamaterials. Metamaterials can alter themselves in response to their post-fabrication environment, for instance, changing their shape depending on their exposure to heat, cold, moisture or light.

One of the key benefits of 4D Printing is its potential to create objects that can self-assemble or self-repair. For example, a printed object may be designed to fold into a specific shape when exposed to heat, allowing it to assemble itself without the need for additional parts or assembly. Similarly, a printed object may be designed to repair itself when damaged by changing its shape or properties in response to a specific stimulus.

Another potential application of 4D Printing is in the field of medicine, where printed objects could be designed to respond to specific stimuli in the body, such as changes in pH or temperature. This could allow for the development of new types of medical implants or drug delivery systems.

This method enables the precise fabrication of dynamic structures, e. g. for the production of artificial muscles for robots, whole bodies for soft robots, or prosthetics. Other goods manufactured in this way include flat-pack furniture, drug capsules, and cardiac stents fine-tuned to respond to body temperature.

Future Perspectives

The overall manufacturing sector could drastically change as 4D Printing becomes cheaper and more accessible. For logistics, shape-changing packages could improve container capacity and even help deal with fragile or perishable cargo. Water management, construction, and manufacturing could benefit from responsive pieces and raise operational efficiency. In the fashion industry, 4D Printing could enable designers to develop products that perfectly fit the user's body.

Image generated by Envisioning using Midjourney